you're dead on........let me make one suggestion. get a smaller bolt.......I had to put a pretty big hole in the sq. tube because the head didn't offer much clearance once I attached the gauged metal. If I build more, I'd go for something in the #8 or #10 range, maybe even with a standard screw type head, that way the shim plate would have a nice little seat. And don't waist your money on buying gauged metal, if you know anyone or work somewhere with a steel banding machine.......the banding works great! Make sure you have a high speed drill when you drill it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Home made tools

- Thread starter Neverdone

- Start date

Help Support Rat Rods Rule:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Mike S.

Well-known member

Sunnybeach

Well-known member

Would there be a problem if aluminum tubing was used for the but clamps?

My thinking is that the aluminum tubing would be easier to cut, especially the slit, on a table saw.

My thinking is that the aluminum tubing would be easier to cut, especially the slit, on a table saw.

Neverdone

He's not done yet...

I would think aluminum would be OK. Don't know if it would give you trouble crushing it down the road?? [S

Dirtyrat

Got Fins?

I would think aluminum would be OK. Don't know if it would give you trouble crushing it down the road?? [S

I would not use aluminum, even the steel ones deflect and have to be re-aligned at times.

Neverdone

He's not done yet...

I would not use aluminum, even the steel ones deflect and have to be re-aligned at times.

Never used a set, wouldn't know.

I don't mean to hijack, but here's how I made mine.

MIKE!!!!!

I found this picture on the other site..........much thanks!!

I built mine from Mike S. I can't take credit for it.

Mike S.

Well-known member

MIKE!!!!!

I found this picture on the other site..........much thanks!!

I built mine from Mike S. I can't take credit for it.

No problem, I am glad they worked for ya. They sure are handy little suckers!

I was gonna add...initially I couldn't get a decent straight line cut across the bottom of the tubing so I made a little table saw fixture for my cut-off wheel. It worked really well and sped the process up a lot.

Attachments

Neverdone

He's not done yet...

Sweet little jig ya made there!!! I am about to make some, but I am also impatient, so I think I am going to slit them with the band saw....

echnidna

Well-known member

they're easy enough to slit with a 4" angle grinder using a 1mm thick stainless steel cutoff disc. Just mark it out with a pencil line and follow the line, golly you only gotta do a slit 1" long . [

Coffee Freak

Well-known member

No problem, I am glad they worked for ya. They sure are handy little suckers!

I was gonna add...initially I couldn't get a decent straight line cut across the bottom of the tubing so I made a little table saw fixture for my cut-off wheel. It worked really well and sped the process up a lot.

Now we are talking - a home-made tool to make.......

home-made tools!!!!

2.3Turbo_T

Well-known member

Here's mine.........1" square tubing, allthread, washer & wingnut, 24 ga sheetmetal (side of a junk microwave) and an 8 penny nail.

Here's mine.........1" square tubing, allthread, washer & wingnut, 24 ga sheetmetal (side of a junk microwave) and an 8 penny nail.

Love your signature man!

Neverdone

He's not done yet...

Looks like most of us have made their own butt weld clamps....

Neverdone

He's not done yet...

My next will be a slip roll and a small break...

jmlcolorado

Well-known member

I didn't post to this one?!

Hum.

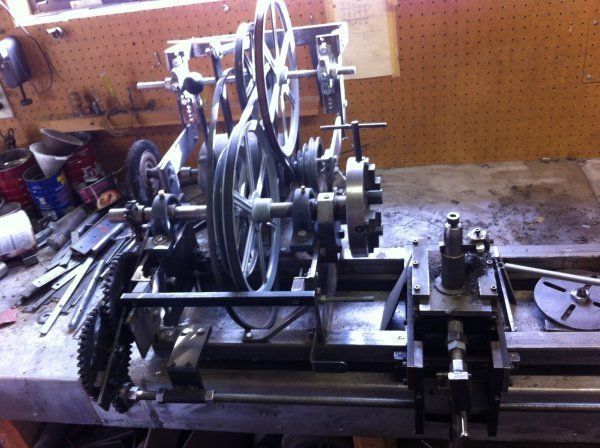

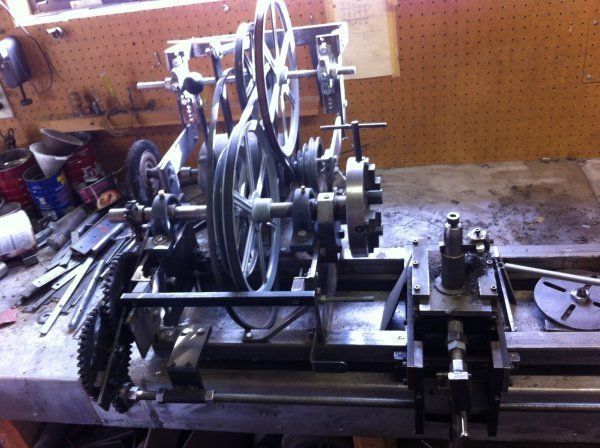

Well here's my contribution. I didn't make it, but I bought it from an old timers son. Apparently the old timer was pretty handy

$50

Hum.

Well here's my contribution. I didn't make it, but I bought it from an old timers son. Apparently the old timer was pretty handy

$50

YBeNormal

Well-known member

So you just move the belts around for different speed

Honestly took me a minute to figure out what it was. I was over thinking it

Honestly took me a minute to figure out what it was. I was over thinking it

Similar threads

- Replies

- 13

- Views

- 3K