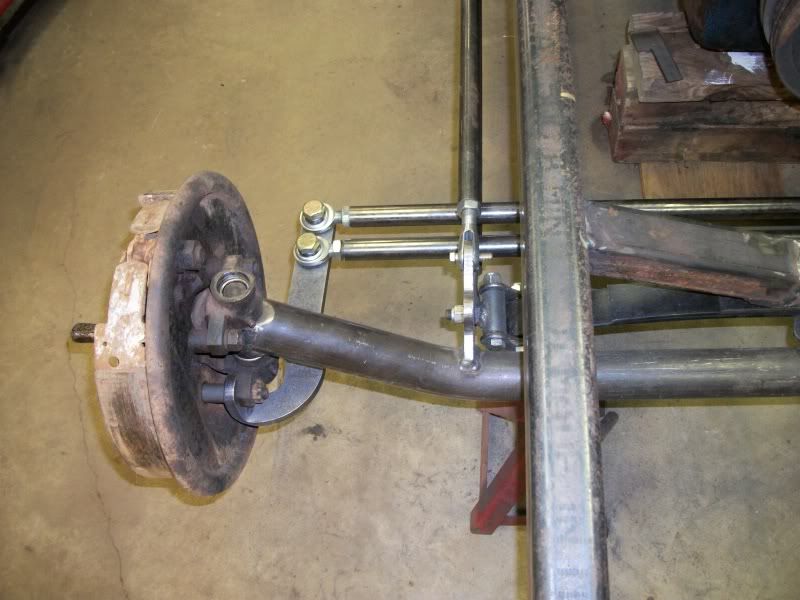

Steering came in last week from EZTBucket.

I installed and tweaked until I got everything to fit.

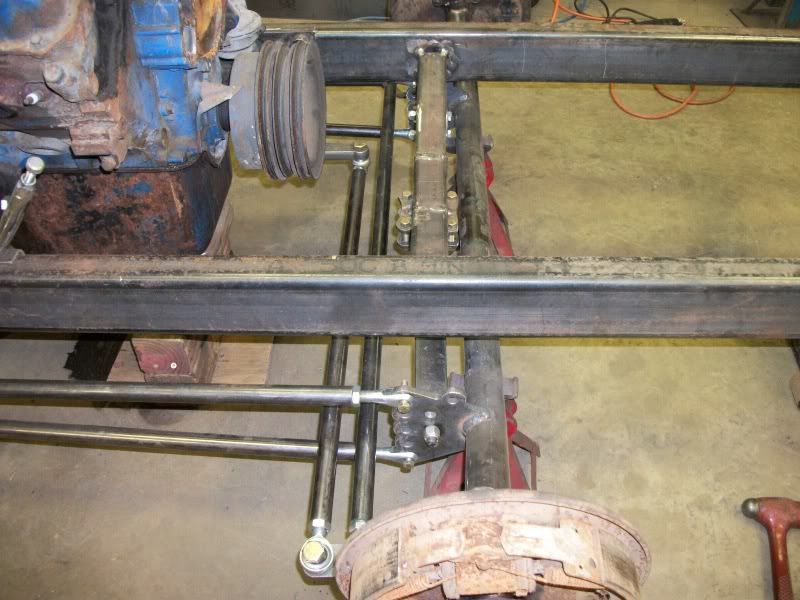

I currently have about 23-24 degrees of steering. My wheel base is gonna end up about 133", so I was hoping for tighter steering, but with spring behind and crossover steering that's about all there is room for.

After I drive it if it's real bad except for parking lots, I could always extend the steering arms 1/4-1/2" to make more room.

What does anyone else have for a turning radius in degrees?

Maybe I should have ordered a 6" drop and spring over? It's hard to tell without an engineering drawing to start with...

I will have about 3" of suspension travel before the axle hits the frame now. I may "C" notch or curve the frame a little later, but thinking it will be enough.

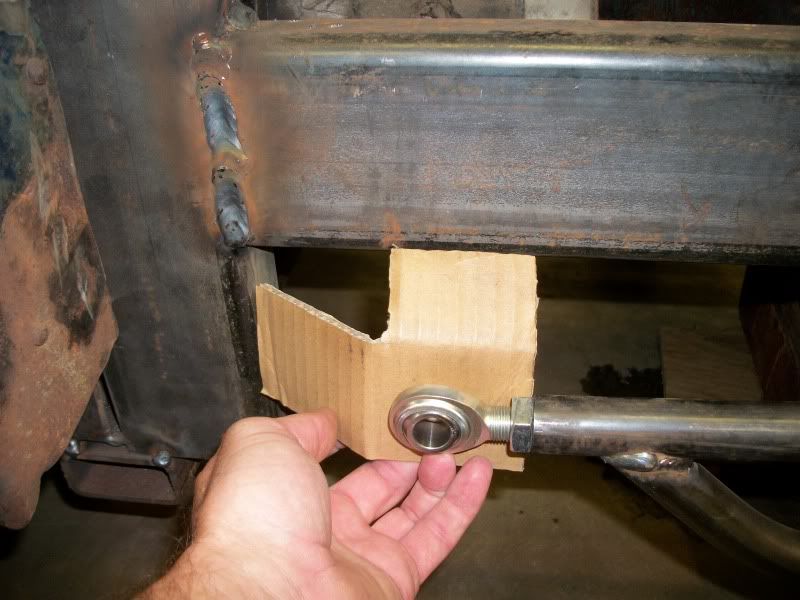

Made some card board templates to start with to save some time. I think I still had a couple hrs. in the first bracket and 15 min. in the second...sigh

I still have ride height adjusting holes where I can go up or down about 1 1/4" if needed.

Hade to make some spacers after I removed the old steering arms because I'm still using drum brakes.

I still need to install and fab brackets for the track bag and the friction shocks. Then I can move on from the front end a bit.

Good news today that I found some used wheels and tires that may fit the bill. I'm gonna see if I can get them stuffed in a rental car if they do...lol

I guess it's hard to contribute sometimes when your skills are so much more advanced than mine

I guess it's hard to contribute sometimes when your skills are so much more advanced than mine