Tango88

Member

As I bought it in Utah. Real short.

Howdy All --- I don't know if my little project is what most folks would call "Rat" or not but here goes. It's a 1946 Chevy school bus that I'm converting into a mini-RV & traveling rig. Plan to keep the outside pretty much as was but replacing the most of the driveline. Have a rebuilt Cummins 4BT (turbo/diesel) that I'm hooking up to a brand new from the factory Allison 6-speed auto. Stuffing it all in the narrow, Art Deco front end should be ... interesting.

I'm a year and a half into it with still a long ways to go but at least my engine & tranny are about ready to start shoehorning in. I do have an album over on Flickr that shows most of it to date. You can see it here...

Tango's Progress Pix

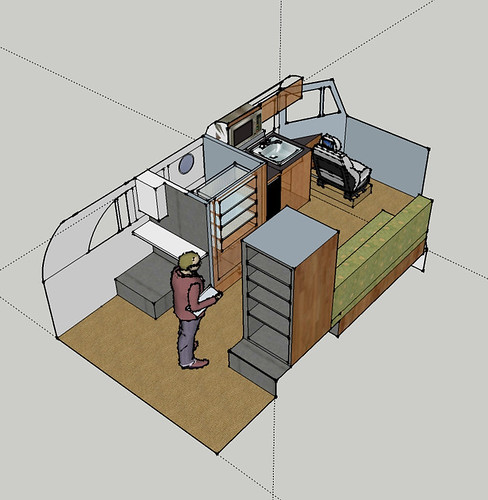

The plan involves keeping the body and chassis pretty much stock. I am building an all steel front door, deleting a couple of windows on each side, constructing a housing in the roof for a window unit A/C and adding a roof deck. The interior will have minimal living quarters. A little jack knife sofa bed, tiny kitchenette and a combination shower/toilet. The rear will be open to carry some of my cement sculpting gear that I tote around the country to teach classes. I have also installed a 44-gallon fuel tank and an equal sized black/gray water tank. One will extend my over the road range to about 1300 miles on a single tank and the other my boondocking stay to about a month.

The bus had a perfectly good 350 Chevy motor and the original, non-synchro 4-speed tranny when I got it, but the combination was only good for about 6 mpg and maybe 45-50 mph. I bought a used Cummins 4BTAA turbo diesel and have rebuilt it throughout and just laid down some big bucks for a factory fresh Allison 2200MH 6-speed auto that together should get me up to highway speeds and yield about 30 mpg. Big difference. I gave the Chevy motor to a bud who runs the ArtCar Museum here in Houston and he is already running it in a sweet little '49 Furd Rat Rod that you guys would love...I'll try to get some pix of it too. I traded the 350 out for assistance installing the diesel package into the bus (and need all the help I can get). Good news is that my friend is calling in his helper who was a diesel mechanic and radical car builder for twenty years, so hopefully it will go about as smoothly as any of these things can ever go.

The biggest challenge at the moment is the rear end. I want to keep the original 20" wheels & tires but getting the gearing right has turned into a nightmare. I had been "told" that the bus had the factory stock 5.43 ring & pinion but it turns out that it was equipped with the "optional" 6.17 granny set. And wouldn't ya know it...the computer model shows that the 5.43 would have been perfect for keeping the Cummins dead on the 1800 rpm sweet spot with the double-overdrive Allison! Problem is, it appears that just about everyone back in those days ordered the granny gears and the "standard" 5.43 sets are scarce as hens teeth. Ya gotta' remember that this bus was built before there was a national highway system and most people were more concerned with hauling a load at 45 than cruising at 65 on rough dirt & gravel roads.

I have been on the hunt for over a year now and no luck so far.

The other option would be to splice a newer center section with more gearing options onto my axles, but I don't have the skill set some of you guys have or the budget to job a project like that out. Not sure where to go from here on this one. I am certainly open to any ideas you folks might have. In the meantime, I have put a ring & pinion request over on the parts wanted section of the forum. Who knows, maybe someone here has one left over from upgrading their project.

This is the basic interior layout done in the free, Google SketchUp program.

Early stage of gutting the interior. The floor was in surprisingly good shape.

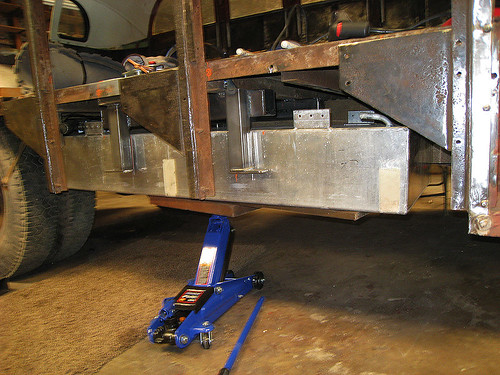

The worst rust was (surprise) around the wheel wells. Had to remake all of the body spacers that fit between the floor & outer skin.

Made the new ones out of galvanized. Should outlive me.

After pulling off the rub rails, I decided to replace all the lower sheet metal. Here's the guide tacked in place for cutting.

...and here's the metal cut away. Much easier to get to the tanks and such now.

Here's the 44 gal. fuel tank being fitted into the mounts I added. It now has a steel rock guard covering the bottom.

The fill neck now comes up through the floor and will be fitted into a locking hatch on the outer skin...some day.

Will post more as time allows, but once again, many thanks to the folks who built this forum and all the creative geniuses who make it so cool & inspiring.