marks63pontiac

Member

Hello. My name is Mark and I'm a GasserHolic and a Rat Rod lover. I'm in the middle of a build using a 1963 full size Pontiac Catalina that's a little on the Rat Rod side. It'll never be pristine show car but hopefully a car worthy of showing.

After moving to Glendale AZ I found a rust free plain old white 2 door hardtop Catalina and snapped it up. The car is being built almost completely by me in my two car garage. I found a good rod builder down here and I had him build the front clip so I knew it was done right and safe. I've build many motors over the years but I had this one built by a very good Pontiac engine guy because I wanted to make sure everything was perfect in this one as I'll soon explain why. Just some specs on the car.

Custom front frame clip using a '57 Chevy pickup front beam axle. Speedway front disc kit. Narrowed rear frame rails to accommodate 31X16.5X15 M/T ET Streets on 15X15 inch rims. They are late light weight rims for now but will be changed out to Cragar SS 14X15 rims to match the fronts. Extra pair of frame rails placed inboard of the original perimeter frame for extra strength that tie into the narrowed rear rails. Braced and bracketed Ford 9 inch with a Detroit locker, 3:50 gears, 35 spline axles with 5/8ths studs. 48 inch ladder bars and custom rear suspension crossmember for the rear springs and shocks.

The firewall has been cut and welded into a cove to move the engine back 11 inches. The front seat and steering has been moved back 11 inches same as the motor. The rear seat area is a shortened padded shelf.

The front sheet metal is bolted together to make a one piece and I used the original inverted hood hinges bolted to the front frame horns to tilt the front end.

The car is built kid of the way someone may have built it back n '63 on a smaller, small shop kind of way. Near shade tree. But the star of the build is the motor.

I've built several turbo cars and I just can't go back to N/A. Soooo.

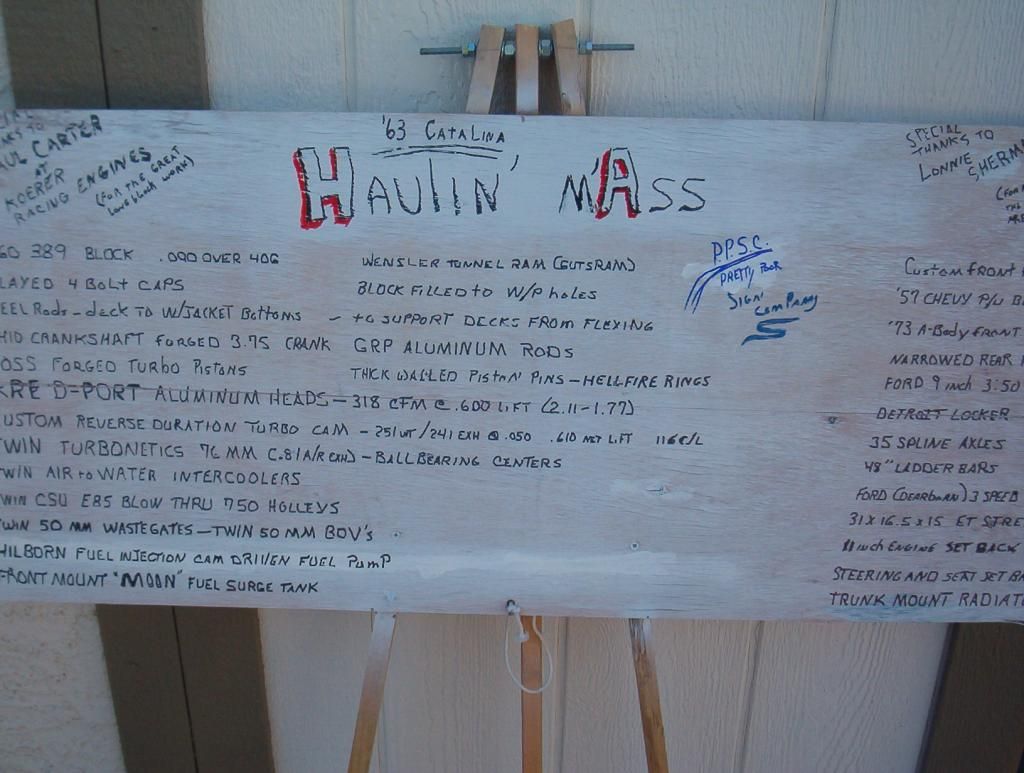

The motor is built with a 1960 389 block bored .090 to 406 cubic inches. The early blocks were cast very thick and heavy. They can withstand a lot of horsepower compared to the thinner cast blocks starting in 1961. But that is where all of the factory stuff stops. Splayed 4 bolt main caps, fully blueprinted block, reinforcing rods inserted into the center decks that reach down to the bottom of the water jackets to stop any deck flexing and gasket problems. Forged Ohio Crankshaft 3.75 crank, GRP aluminum rods, Ross turbo dished lightweight pistons and pins. Hellfire rings. Special order solid roller turbo cam with reverse duration 251 int and 241 exhaust at .050 116 CL .601/.601 net lift and the 4/7 swap.

The heads are KRE aluminum D-Ports flowing 318 @ .600 lift, 2.11 and 1.77 valves. 65cc chambers hence the dished pistons to get about 9.00 to 1 compression.

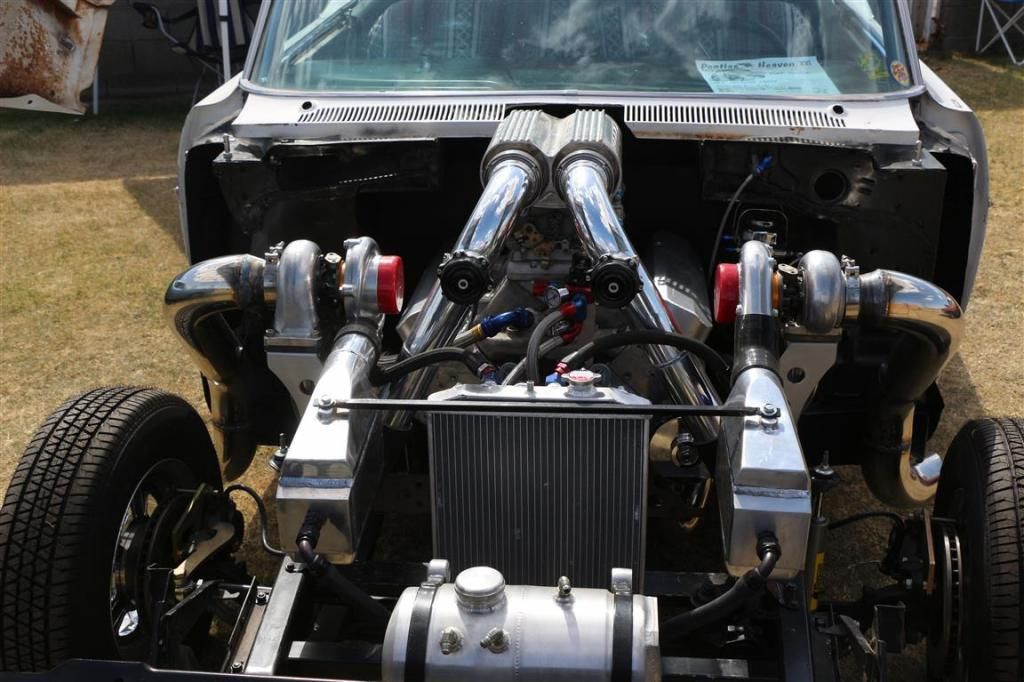

Twin Turbonetics TC76 ball bearing turbos, twin 50MM waste gates, twin 50MM blow off valves, blowing thru twin air to water intercoolers and into twin 750 Holley CSU blow thru E85 carburetors. This all blows into a Wenzler GutsRam tunnel Ram intake. I've modified a SHOGUN twin opening blower scoop to act as the carb hat. I plan on making an easy 1000 HP for everyday use and boosting it up to 1500 for the strip. It may never hit those numbers but that is my goal. My previous single turbo Pontiac 455 in a '73 Trans Am hit 1065 HP on 15 psi and pump gas. This is capable of 25 psi and it's on E85.

Right now the power is going thru a 1965 Pontiac (GM) version of the Ford Top Loader 3 speed transmissions that GM bought from Ford back then. This will all eventually get changed out to a built 4L80E/lockup converter some time in the future.

Although still not running yet it is very close. The last car show I took it to I had it in its final configuration and all together and this is what it looked like.

I currently have the motor and drivetrain back out to do several things to it. One of which is getting a complete cage built in for the strip. I still have a lot of things to do yet but I hope to have it at least running by spring. If I'm lucky maybe even on the road. That I can't wait to do.

Mark

After moving to Glendale AZ I found a rust free plain old white 2 door hardtop Catalina and snapped it up. The car is being built almost completely by me in my two car garage. I found a good rod builder down here and I had him build the front clip so I knew it was done right and safe. I've build many motors over the years but I had this one built by a very good Pontiac engine guy because I wanted to make sure everything was perfect in this one as I'll soon explain why. Just some specs on the car.

Custom front frame clip using a '57 Chevy pickup front beam axle. Speedway front disc kit. Narrowed rear frame rails to accommodate 31X16.5X15 M/T ET Streets on 15X15 inch rims. They are late light weight rims for now but will be changed out to Cragar SS 14X15 rims to match the fronts. Extra pair of frame rails placed inboard of the original perimeter frame for extra strength that tie into the narrowed rear rails. Braced and bracketed Ford 9 inch with a Detroit locker, 3:50 gears, 35 spline axles with 5/8ths studs. 48 inch ladder bars and custom rear suspension crossmember for the rear springs and shocks.

The firewall has been cut and welded into a cove to move the engine back 11 inches. The front seat and steering has been moved back 11 inches same as the motor. The rear seat area is a shortened padded shelf.

The front sheet metal is bolted together to make a one piece and I used the original inverted hood hinges bolted to the front frame horns to tilt the front end.

The car is built kid of the way someone may have built it back n '63 on a smaller, small shop kind of way. Near shade tree. But the star of the build is the motor.

I've built several turbo cars and I just can't go back to N/A. Soooo.

The motor is built with a 1960 389 block bored .090 to 406 cubic inches. The early blocks were cast very thick and heavy. They can withstand a lot of horsepower compared to the thinner cast blocks starting in 1961. But that is where all of the factory stuff stops. Splayed 4 bolt main caps, fully blueprinted block, reinforcing rods inserted into the center decks that reach down to the bottom of the water jackets to stop any deck flexing and gasket problems. Forged Ohio Crankshaft 3.75 crank, GRP aluminum rods, Ross turbo dished lightweight pistons and pins. Hellfire rings. Special order solid roller turbo cam with reverse duration 251 int and 241 exhaust at .050 116 CL .601/.601 net lift and the 4/7 swap.

The heads are KRE aluminum D-Ports flowing 318 @ .600 lift, 2.11 and 1.77 valves. 65cc chambers hence the dished pistons to get about 9.00 to 1 compression.

Twin Turbonetics TC76 ball bearing turbos, twin 50MM waste gates, twin 50MM blow off valves, blowing thru twin air to water intercoolers and into twin 750 Holley CSU blow thru E85 carburetors. This all blows into a Wenzler GutsRam tunnel Ram intake. I've modified a SHOGUN twin opening blower scoop to act as the carb hat. I plan on making an easy 1000 HP for everyday use and boosting it up to 1500 for the strip. It may never hit those numbers but that is my goal. My previous single turbo Pontiac 455 in a '73 Trans Am hit 1065 HP on 15 psi and pump gas. This is capable of 25 psi and it's on E85.

Right now the power is going thru a 1965 Pontiac (GM) version of the Ford Top Loader 3 speed transmissions that GM bought from Ford back then. This will all eventually get changed out to a built 4L80E/lockup converter some time in the future.

Although still not running yet it is very close. The last car show I took it to I had it in its final configuration and all together and this is what it looked like.

I currently have the motor and drivetrain back out to do several things to it. One of which is getting a complete cage built in for the strip. I still have a lot of things to do yet but I hope to have it at least running by spring. If I'm lucky maybe even on the road. That I can't wait to do.

Mark