That's a good tip about the cut up belt........I will have to remember that one.

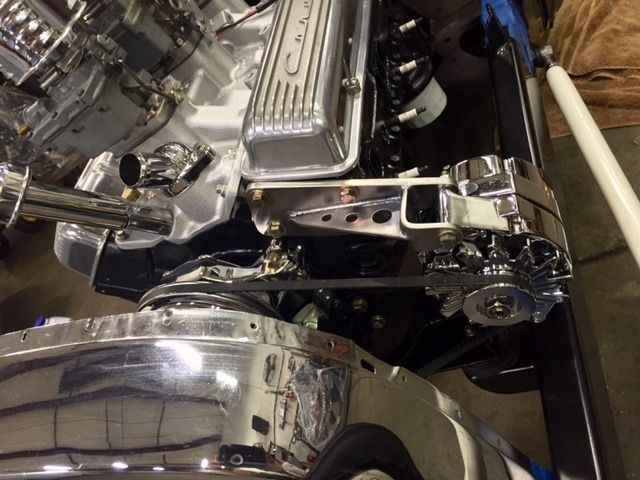

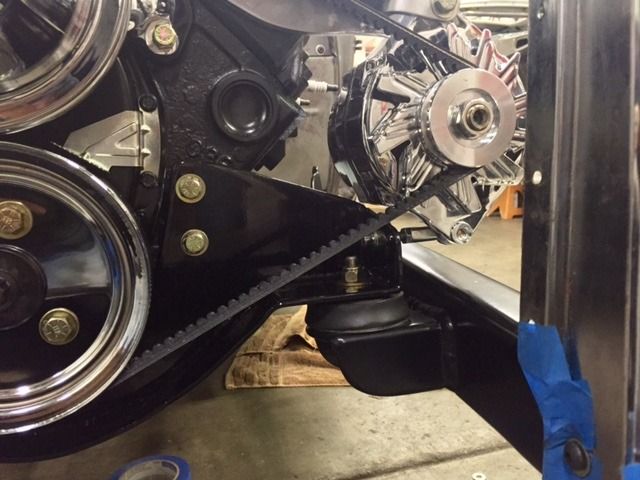

Today I worked on my headers, bolted the flanges on and started mocking up bends. I called Summit to get some 8 foot straight pieces of exhaust tubing and they were completely out, so I rethought the process.

If I get Dan involved to weld them up for me, it will be a very long, drawn out affair. He can never do anything simple, and his own headers took him two weeks to build. I really don't want them to drag out that long or to try to corral him long enough to finish them up for me, so I went to plan B.

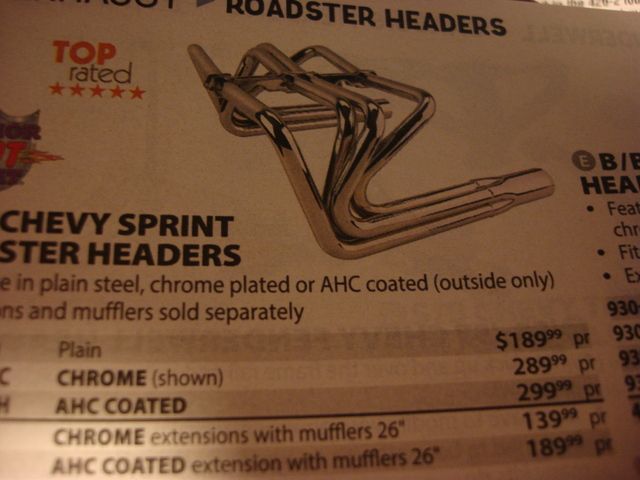

I was planning on ordering these headers for my altered project from Speedway, so I called them and will have this set on Wednesday:

I got the coated ones and if I don't like the look on the rpu, I will simply put them away for the altered and go to plan C. (I don't have a plan C yet.

)

I am just tired of messing around with this rpu project and want to get on to the altered asap, so this will get one more problem out of the way.

My original plan was to have The Brassworks build me a radiator for this one, just like they did for my 27, but they are a little pricey. I don't feel like spending another $1000.00 on a radiator, so I called PRC, who has built some aluminum ones for us in the past (my 23 had one and so does Dan's rpu). They are at $ 500.00, so I am going to order it there, probably next week or so.

Don