offroadrolls

Well-known member

Yesterday I was pumped to move a couple water tanks into a massive hole I dug for another 3700 gallons of fresh water storage.

Then it started to rain . What a momentum killer that was. Not being very good a changing directions, I took a nap. Turns out, a nap was all I needed to find some momentum in a different direction. So I went down to the shop and built some mounting brackets to incorporate the Silver Cloud cross member/motor mount doo-hickey on to the 27 frame.

. What a momentum killer that was. Not being very good a changing directions, I took a nap. Turns out, a nap was all I needed to find some momentum in a different direction. So I went down to the shop and built some mounting brackets to incorporate the Silver Cloud cross member/motor mount doo-hickey on to the 27 frame.

But first, the remaining part of the old motor mounts needed to be ground off.

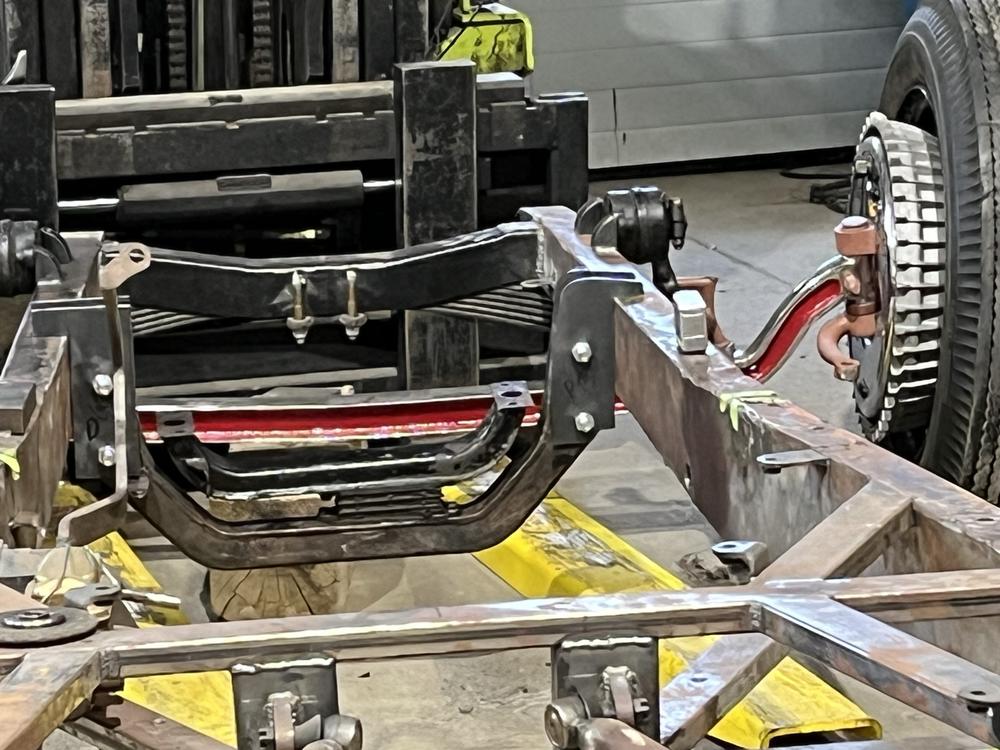

Here's the cross member/ motor mount thingamajig.

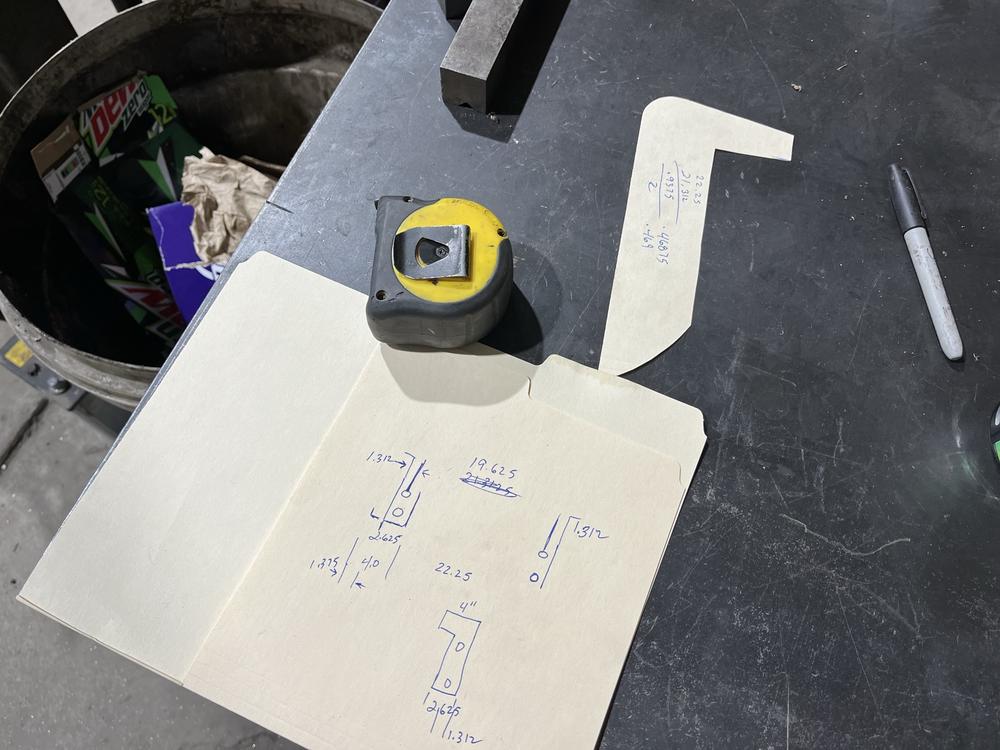

Figure out dimensions

Not pretty yet but dimensions worked out.

Starting to look better but too fat on top

I liked this so I went with it.

Here's all nuts bolts and washers that were used on the Rolls. Looks like I lost one of the 16 washers.

Finished.....I think.

From here the engine can be dropped in and set in the correct position Then the brackets will be tack welded to frame, engine lifted back out, and brackets finish welded.

Then it started to rain

But first, the remaining part of the old motor mounts needed to be ground off.

Here's the cross member/ motor mount thingamajig.

Figure out dimensions

Not pretty yet but dimensions worked out.

Starting to look better but too fat on top

I liked this so I went with it.

Here's all nuts bolts and washers that were used on the Rolls. Looks like I lost one of the 16 washers.

Finished.....I think.

From here the engine can be dropped in and set in the correct position Then the brackets will be tack welded to frame, engine lifted back out, and brackets finish welded.

Attachments

-

IMG_9207.jpg218.4 KB · Views: 73

IMG_9207.jpg218.4 KB · Views: 73 -

IMG_9210.jpg159.8 KB · Views: 71

IMG_9210.jpg159.8 KB · Views: 71 -

IMG_9212.jpg88 KB · Views: 68

IMG_9212.jpg88 KB · Views: 68 -

IMG_9214.jpg171.7 KB · Views: 67

IMG_9214.jpg171.7 KB · Views: 67 -

IMG_9216.jpg117.1 KB · Views: 68

IMG_9216.jpg117.1 KB · Views: 68 -

IMG_9217.jpg145.2 KB · Views: 8

IMG_9217.jpg145.2 KB · Views: 8 -

IMG_9218.jpg158.7 KB · Views: 67

IMG_9218.jpg158.7 KB · Views: 67 -

IMG_9219.jpg111.6 KB · Views: 68

IMG_9219.jpg111.6 KB · Views: 68 -

IMG_9220.jpg160.7 KB · Views: 69

IMG_9220.jpg160.7 KB · Views: 69 -

IMG_9215.jpg130.8 KB · Views: 67

IMG_9215.jpg130.8 KB · Views: 67