You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1951 Ford F1/F150 fusion

- Thread starter mine_us_3

- Start date

Help Support Rat Rods Rule:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

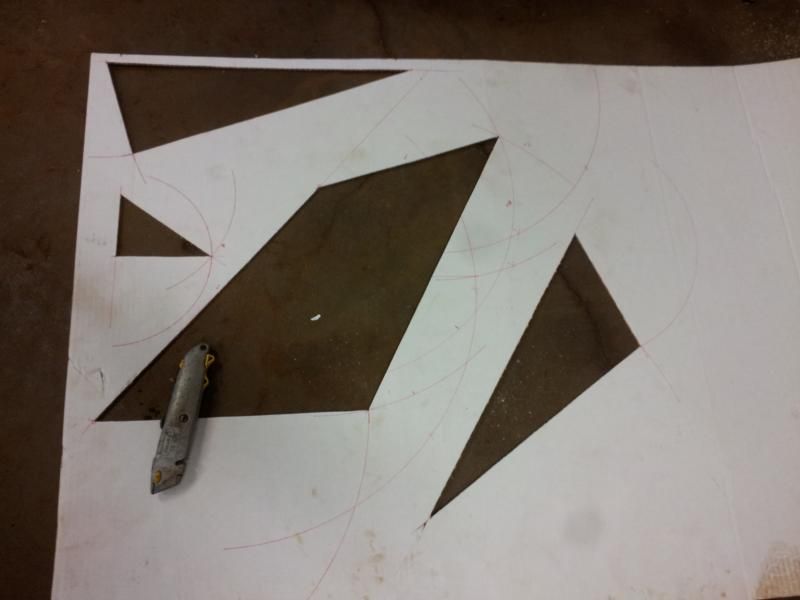

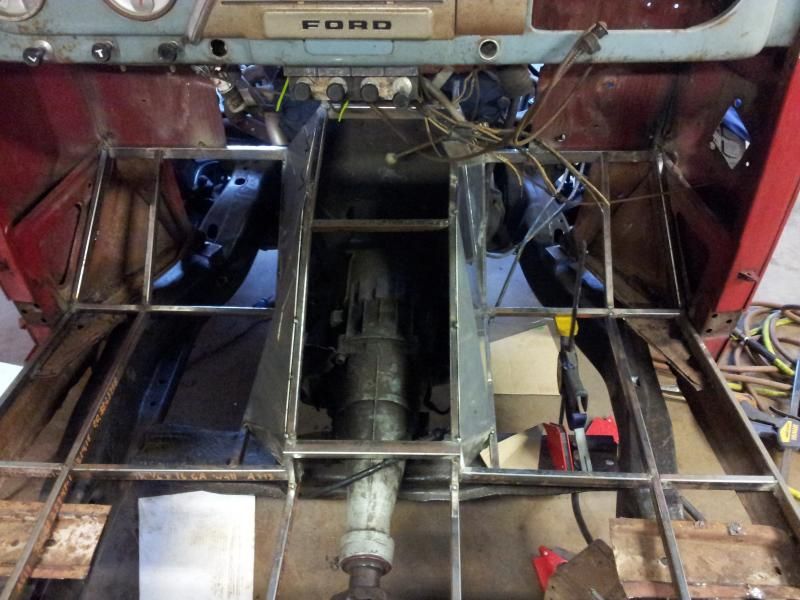

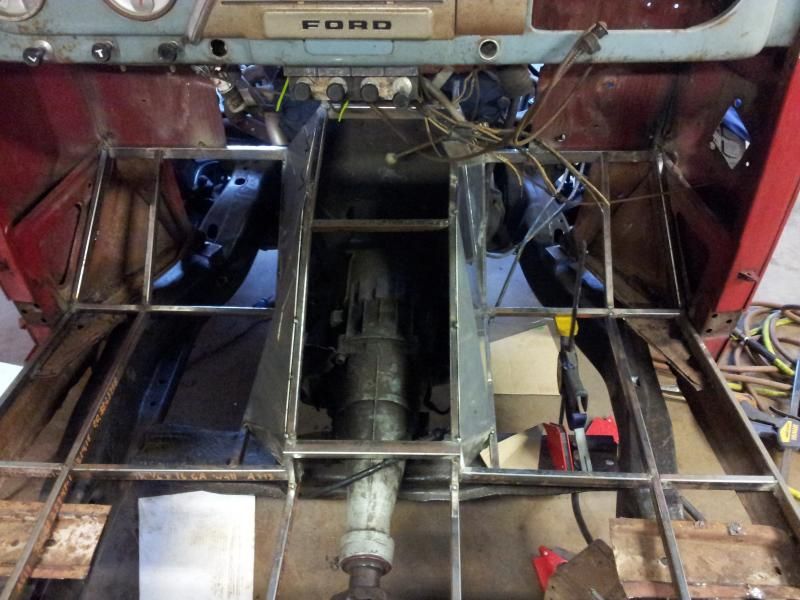

Next is to cut the steel. Here is where it gets interesting. The only sheet metal I had was 11 ga. 316 Stainless Steel. Work with what you have right?? I cut the stainless with a grinder and cutting wheels then bent it in a vise.

I did the same thing for the center piece where the Windstar shifter will go.

I did the same thing for the center piece where the Windstar shifter will go.

I re-mounted the cab and pulled the steering column out of the F150. I had to take apart the column and shorten it up about a foot to get the lengths needed to fit in the truck. I made a mount that connected to the bottom of the dash.

I now need to make a shaft to go from the column to the steering box. I used PTO links, F150 shaft parts, and some scrap steel. I milled down a piece of round stock to make a longer notched piece as seen below.

I now need to make a shaft to go from the column to the steering box. I used PTO links, F150 shaft parts, and some scrap steel. I milled down a piece of round stock to make a longer notched piece as seen below.

I now decided to hang the doors. This was a pain because some of the door pins were broke. I had to pound them out and replace them with extras I had.

Picked up a different set of headers from Craigslist. These are shorties off of a Mustang. They fit with no modification to go past the steering shaft.

Picked up a different set of headers from Craigslist. These are shorties off of a Mustang. They fit with no modification to go past the steering shaft.

Next I scored a 8.8" ford Explorer rear end from a guy at work for $25. I will probably not use it right away but rebuild it and when the time is ready then I will put it in.

Now...I need to make the gas tank mounts. This tank is off of a GM? I have no idea. I welded the upper mounts to the frame. Then I made the strap out of a piece of 304 SS sheet metal by cutting them by hand. the bolted everything together. I used a bicycle tire cut into sections to go between the strap and the tank.

Now...I need to make the gas tank mounts. This tank is off of a GM? I have no idea. I welded the upper mounts to the frame. Then I made the strap out of a piece of 304 SS sheet metal by cutting them by hand. the bolted everything together. I used a bicycle tire cut into sections to go between the strap and the tank.

Next up...cut the box. I needed to take out 6 11/16" out of the front of the box to I wouldn't have to re-drill all of the fender mounting holes.

Also accounting for the cutting wheel width.

Needed to make room for the tires because they are narrower than the width of the bed. I had to cut out arches.

Also accounting for the cutting wheel width.

Needed to make room for the tires because they are narrower than the width of the bed. I had to cut out arches.

Here you can see how wide the tires are compared to the width of the bed.

Next I welded and bolted bars to the frame and bed sides.

I wanted to see the ride height so I put on the rear fenders. They are just clamped in place.

This is where I am at for now. I will keep taking pictures and uploading. Thank you for the comments!

Next I welded and bolted bars to the frame and bed sides.

I wanted to see the ride height so I put on the rear fenders. They are just clamped in place.

This is where I am at for now. I will keep taking pictures and uploading. Thank you for the comments!

Flipper_1938

He recycles the right way

Cool build [P

Old Iron

Well-known member

Good build you have going [cl

I would suggest one thing. Where the brake bracket is mounted to the firewall sandwich a piece of 3/16"x8"x8" plate between there as you'll have a lot of firewall movement from the pressure when braking.

I would suggest one thing. Where the brake bracket is mounted to the firewall sandwich a piece of 3/16"x8"x8" plate between there as you'll have a lot of firewall movement from the pressure when braking.

The bracket is from an F150 and how they had it connected was bolted to the flimsy firewall and then the bracket bolted to the steering column. I think I will build a bracket that I can bolt the F150 piece to and then bolt it to the steering column again. It will essentially make a triangle which will be pretty strong. Worst case, I feel some sponge and do as you instructed. Thank you for the input!

Country Misfit

I tell you... I get no respect!

Thats a nice looking ride. Great fab. work.

Bamamav

Well-known member

Dig the Aerostar shifter. Got one myself I'm going to put in Bubba's F100 one of these days.

Oldrodder43

Well-known member

Very inventive fabbing! And I wish I had your welding skills. I barely make it with an Arc Welder. Even MIG is too much for me, at least on sheet metal. You are doing great. Makes me green----------