GJunktionMike

Something's wrong with that boy!

Your still alive [cl How clean do you have to get the bars for the brass to stick.

Thanks man! I'm pretty impressed with my own work tooDang dude! You always impress me with your work. Cant wait to see the grill all done up. Now get of yer brass and finish it up. Lol great work. RR

Your still alive [cl How clean do you have to get the bars for the brass to stick.

I'm really diggin' the truck bro!! The brass accents are the cats ass!!!

Wow, you are truckin' right alongMakes me ashamed of my progress

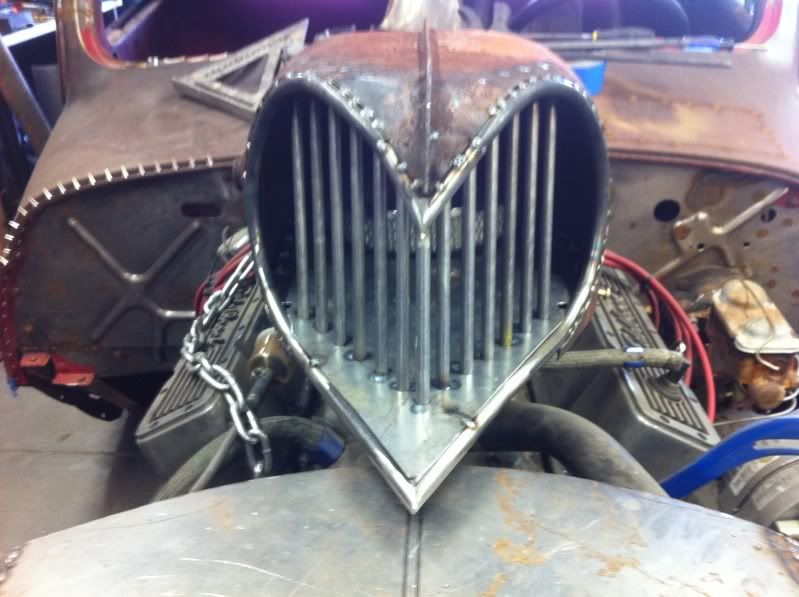

Love how the scoop and grille turned out and that tunnel work is top notch as well! [cl[cl[cl

Thanks for the flat glass info too, I'll be needing some for my Willys. As for using safety glass for the sides and back just say you are doing it for sound proofingMy son in-law was noticing the laminated side glass in my '57 Chevy the other day and said that some car makers are now touting laminated side glass as the latest thing in quieter cars like it is something new

Carry on with the "Cool Binder"

Next time you roll it outside, take a full side shot of it if you would.

Nice build!

I'm not sure if your actually considering chopping another inch, but if you would, I wonder if lowering the front of the roof above the windshield and taking a pie out of the sides of the roof would be easier than cutting all the doors and windshield frame again? I saw that done in a magazine on another truck once anyway so they didn't have to cut the windshield on it at all.

That's a good enough pic. Thanks. I was curious how the front overhang looked. Not bad.

Is your door window taller in the front than the back?

Crap. I know what would make it look better. I need the roof front to be chopped 1 more inch

This was my first chop so I didn't know chopping the same all the way around would give a nose up look.

Enter your email address to join: