You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

rack & pinion straigt axle set up

- Thread starter wannaby

- Start date

Help Support Rat Rods Rule:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

dogpatch1

Well-known member

installed one of these for a customer on his 32 with a straight axle and powersteering. check em out.

no limit engineering dp1

http://nolimit.net/prodinfo.asp?number=PS-SA-

no limit engineering dp1

http://nolimit.net/prodinfo.asp?number=PS-SA-

bob w

Still crazy after all these years!

I have rack & pinion steering on 3 rods. Two have beam axles and one has a tube axle. I used a VW Sirocco and two Geo racks. All are mounted to the axle. There is a slip joint between the pinion shaft and the steering shaft to allow for length changes when hitting bumps. Since these were installed before I got a digital camera, I don't have any construction pics. I'm very satisfied with all these installations.

Rev Tex Devlle

He's workin' 4 da Lord, in a '46 Ford!

I have rack & pinion steering on 3 rods. Two have beam axles and one has a tube axle. I used a VW Sirocco and two Geo racks. All are mounted to the axle. There is a slip joint between the pinion shaft and the steering shaft to allow for length changes when hitting bumps. Since these were installed before I got a digital camera, I don't have any construction pics. I'm very satisfied with all these installations.

hey bob been think bout doin the same! would you just have a pic of the slip joint or tell me what you used and maybe some ruff measurements?

Ratcrazy

Well-known member

Bob, I too am interested in the slip joint and also the mounting brackets. Could you post some close up pictures of both?

I bought a 88 Dodge Omni rack to use on my 50 Chevy straight axle and would appreciate some details on how you went about developing this set up.

Thanks

Larry

I bought a 88 Dodge Omni rack to use on my 50 Chevy straight axle and would appreciate some details on how you went about developing this set up.

Thanks

Larry

Pookie Bros

The Deacon of Diesel!

Pics of them installed PLEASE

bob w

Still crazy after all these years!

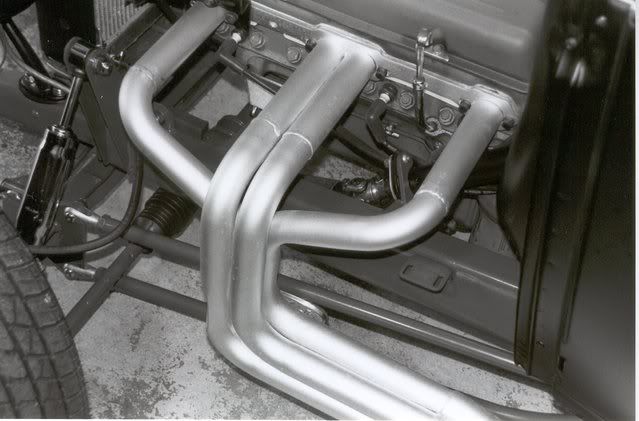

Here's the VW Sirocco R & P on a '31 Model A. Follow the steering shaft to the u-joint. On the left end of the joint is a double D shaft. It runs into a double D sleeve. Those two parts make up the slip joint. They move in and out about 1/4" to absorb the motion of the front axle on bumps and holes in the road. The engagement between the 2 parts is around 6" so the stresses are dissipated over a lot of material.

You can see, if you look closely, that the rack is bolted to 1" by 2" .120 wall rectangular tubing that is welded to the I-beam axle The R & P rubber mounts and the associated U-clamps are used. The R & P is positioned where the original tie rod was located.

I have experienced no bump steer or any other bad handling or steering behavior with this set up. I hope this helps.

Last edited:

bob w

Still crazy after all these years!

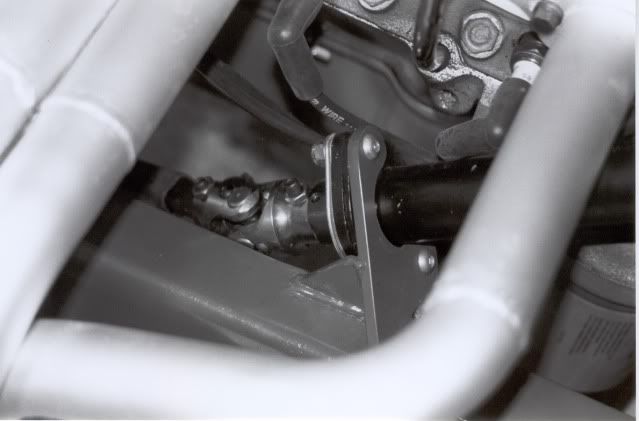

A closer shot. These are the only pics I have & the car is stored where I can't get any good shots.

Sniper

Canadian Rust Bucket

Check out the Sept. issue of Rod & Custom. They have a tech feature of a rack and pinion going on a dropped axle Model A. Sniper

Sniper

Rev Tex Devlle

He's workin' 4 da Lord, in a '46 Ford!

A closer shot. These are the only pics I have & the car is stored where I can't get any good shots.

yeah i see,, i thought that would work ,, just needed to see it, the only thing that concrned me was, if you pulled off a uneven surface, where one wheel went up and the other down, i saw a buddy of mine put r&p on him truck, but it looked like it would have travel problems, so I thought why not mount it to the axle and just have a joint just like what i see you have. and driving my old truck i watched the front end travel as i pulled into my drive way and wondered about uneven surfaces, do you have any advice about any possible problems with this! see i live in a county with bad bad roads,, the one in front of my house although paved , would probly be better if it was dirt~~~!!!!!

bob w

Still crazy after all these years!

Rev, I think the 2 u-joints in the steering shaft compensate for times when there is a lot of front axle tilt. I haven't experienced any problem caused by bad roads or irregulat surfaces and we have plenty of them around here.

Rev Tex Devlle

He's workin' 4 da Lord, in a '46 Ford!

hey bob ,, so i started this and did some mock up, what do you think? any changes that i might need to do!! i use the brackets of a 48 ford, the bracket are the shock mounts and spring clamps for the rear axle, cast , very strong and about 1 inche thick, i use grade 8 bolts , and o also use two bolts that are used as jam nut locks against the axle to reduce the risk of side to side movement!

Attachments

Last edited:

Similar threads

- Replies

- 16

- Views

- 1K