lowbudget50

Creators of all things awesome

- Joined

- Sep 23, 2012

- Messages

- 6,026

Love those motors!!! [cl

BoB

Did you use the alignment tool for the front and rear crankshaft seals?

The first few I put together I got away with one but had to go back and redo two of them to stop the oil leaks.

Yaaa on the oil

Booo on the tranny

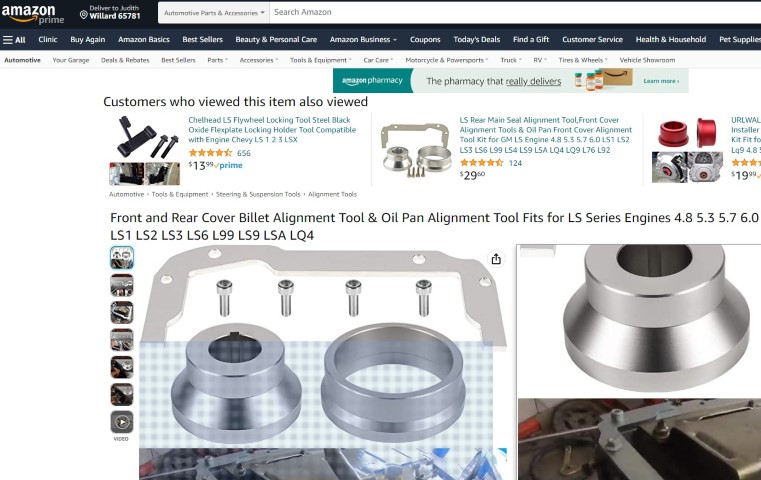

https://www.amazon.com/Front-Cover-Billet-Alignment-Engines/dp/B088W435KX

Did you use an oil pickup tube o-ring that you had to use a little force to push it into the oil pump or did it slip right in?

I've had this issue and found out I had used too small of an o-ring out of the gasket kit.

That sucks man... I hope you will find the problem before you have to buy a hemi.

Enter your email address to join: