cking894

Well-known member

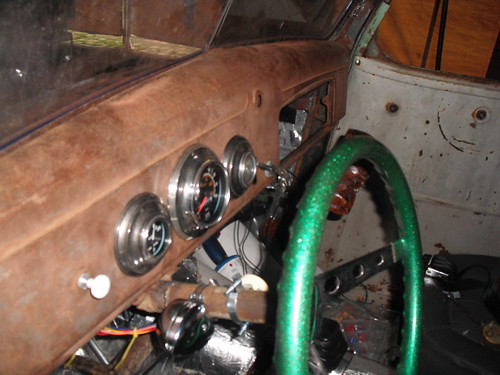

I got my gauges installed in the dash yesterday. I think they look pretty good.

We also got the truck off the jack stands and drove it out of the shop. My rear suspension was to soft and let it sit to close to the ground. We had to move the coil overs so they stand more up right. By doing that it stiffened the suspension and we were able to get the ride height just right. Unfortunately we didn't get done with that until 10:00 last night.

I feel pretty good about the who thing. It has taken us just under five months to build and I'm off to get it registered today. I'll post some of the videos we took later.

Keith

We also got the truck off the jack stands and drove it out of the shop. My rear suspension was to soft and let it sit to close to the ground. We had to move the coil overs so they stand more up right. By doing that it stiffened the suspension and we were able to get the ride height just right. Unfortunately we didn't get done with that until 10:00 last night.

I feel pretty good about the who thing. It has taken us just under five months to build and I'm off to get it registered today. I'll post some of the videos we took later.

Keith