IRON MAIDEN

Well-known member

Well I picked up a motor today. I'm not too knowedgable about Chevy motors but it seemed like a good deal. I was hunting for a low mileage 350/350 combo and figured I could just add some performance goodies along the way.

But found this motor freshly rebuilt with the performance goodies already there. Not sure what kind of power I will get out of it but I'm guessing around 300-325hp. I will try to find a rebuilt 700R4 transmission to mate up to it.

Here is what he had advertised on the motor....

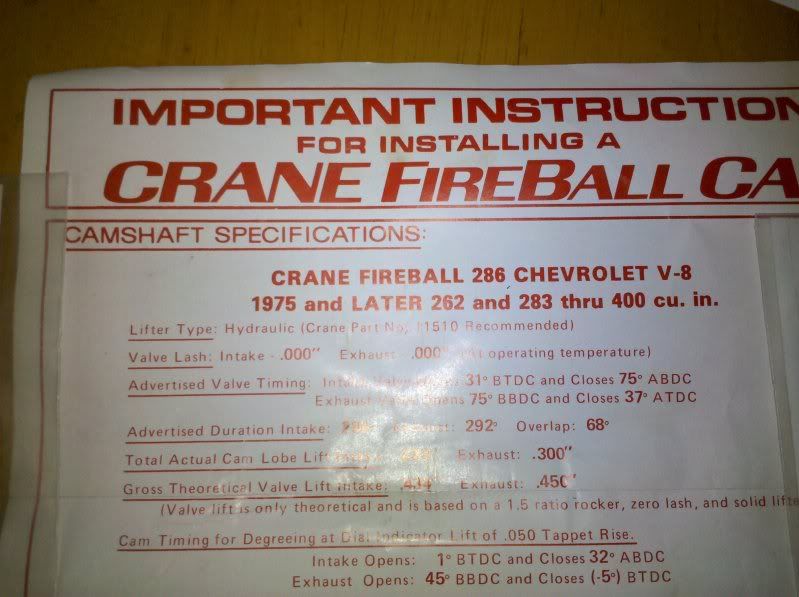

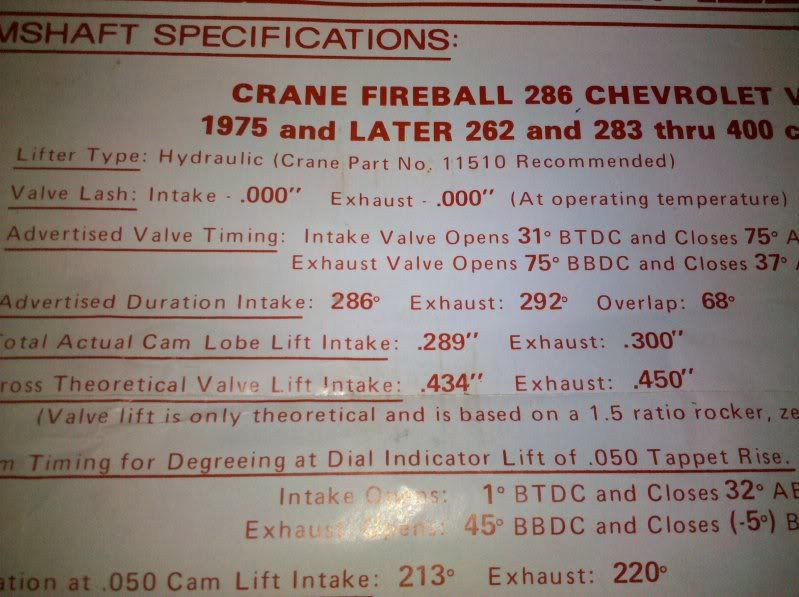

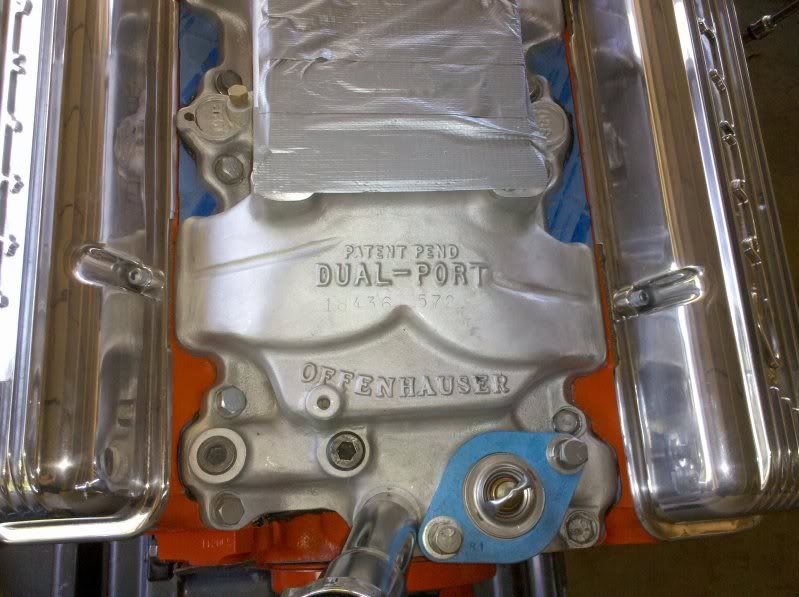

Rebuilt 63 Corvette 327 Engine

This engine came out of a 1963 Corvette Split Window I recently bought. I’m putting a stoker motor in the ’63 so this is for sale. Block was bored to .060” over with new TRW pop up pistons with molly rings, double roller riming chain turns a new Crane Fireball cam with advertised duration of 286°. Block also has new cam bearings and freeze plugs. Crank was turned to .020”-.020” with new Clevite rod and main bearings – new high volume oil pump with hypo intermediate shaft. Heads are angle plug Fuely Double hump with stainless 2.02” intakes and 1.60” exvalves. Heads are street ported (reworked bowls and gasket matched). Heads have screw in studs with CompCam guide plates with Hypo 3/8” pushrods. Heads just redone with new guide bushings, perfect circle seals and perfect 3 angle valve job with LTI springs. Valve covers are genuine Corvette highly polished. Intake is Offenhauser 360° equa-flow manifold that is gasket matched to heads. Included is a junk QuadraJet carb that’s been sitting in a box for 25 years. I would recommend a new Edlebrock (manifold is for AFB, QuadraJet type carbs – Hollys don’t fit). The factory Hypo Rams Horn exhaust manifolds with 2-1/2 outlets are also available for extra money; flywheel also available. Engine built by El Mirage 200 MPH and Bonneville 200 MPH Club member with 40 years of race engine building experience.

But found this motor freshly rebuilt with the performance goodies already there. Not sure what kind of power I will get out of it but I'm guessing around 300-325hp. I will try to find a rebuilt 700R4 transmission to mate up to it.

Here is what he had advertised on the motor....

Rebuilt 63 Corvette 327 Engine

This engine came out of a 1963 Corvette Split Window I recently bought. I’m putting a stoker motor in the ’63 so this is for sale. Block was bored to .060” over with new TRW pop up pistons with molly rings, double roller riming chain turns a new Crane Fireball cam with advertised duration of 286°. Block also has new cam bearings and freeze plugs. Crank was turned to .020”-.020” with new Clevite rod and main bearings – new high volume oil pump with hypo intermediate shaft. Heads are angle plug Fuely Double hump with stainless 2.02” intakes and 1.60” exvalves. Heads are street ported (reworked bowls and gasket matched). Heads have screw in studs with CompCam guide plates with Hypo 3/8” pushrods. Heads just redone with new guide bushings, perfect circle seals and perfect 3 angle valve job with LTI springs. Valve covers are genuine Corvette highly polished. Intake is Offenhauser 360° equa-flow manifold that is gasket matched to heads. Included is a junk QuadraJet carb that’s been sitting in a box for 25 years. I would recommend a new Edlebrock (manifold is for AFB, QuadraJet type carbs – Hollys don’t fit). The factory Hypo Rams Horn exhaust manifolds with 2-1/2 outlets are also available for extra money; flywheel also available. Engine built by El Mirage 200 MPH and Bonneville 200 MPH Club member with 40 years of race engine building experience.